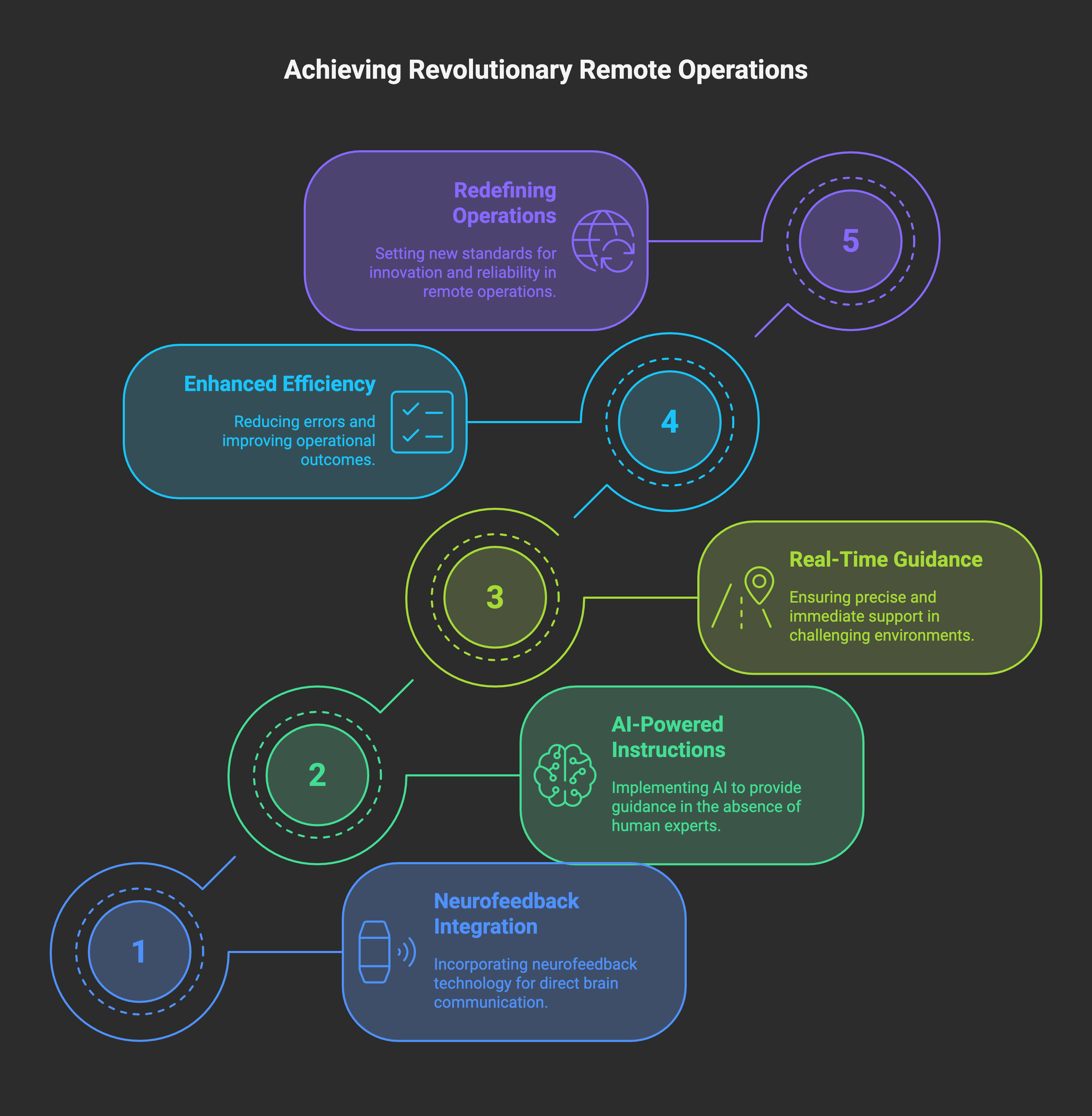

StriveGrid Engineering Guide Platform is set to revolutionize remote operations by becoming the first platform to leverage neurofeedback for transmitting instructions. This cutting-edge innovation means that an operator in the field only needs to wear a brain-computer interface (BCI), allowing instructions from a remote engineer or technical expert to be seamlessly transmitted directly to their brain via neurofeedback.In scenarios where a remote engineer is unavailable, the system utilizes AI-powered instructions, which are also directly relayed to the operator's brain. This eliminates reliance on traditional communication channels, significantly reducing the risk of errors and enhancing operational efficiency.By integrating neurofeedback and AI, the Hustler Joint System Engineering Guide Platform ensures precise, real-time guidance, even in the most challenging environments. This groundbreaking approach is poised to redefine how complex operations are conducted, setting a new standard for innovation and reliability.StriveGrid Engineering Guide Platform is a cutting-edge solution that leverages Digital Twin Technologies to enhance operational efficiency, reduce downtime, and improve decision-making across industries like manufacturing, oil and gas, and utilities.Augmented Reality for Troubleshooting

Real-Time Guidance

The platform integrates AR to provide engineers and frontline workers with real-time instructions and visual aids when performing repairs or maintenance tasks. Workers can view digital twins overlaid on the physical equipment, with detailed operational data and step-by-step guidance.Remote Expert Assistance

The AR system also facilitates remote expert assistance, allowing specialists to guide workers through complex procedures in real-time, with both parties seeing the same augmented view of the equipment.Improved Accuracy

AR and real-time guidance streamline repair processes, reducing the time it takes to troubleshoot and fix issues, while also improving the quality of repairs by reducing human error.

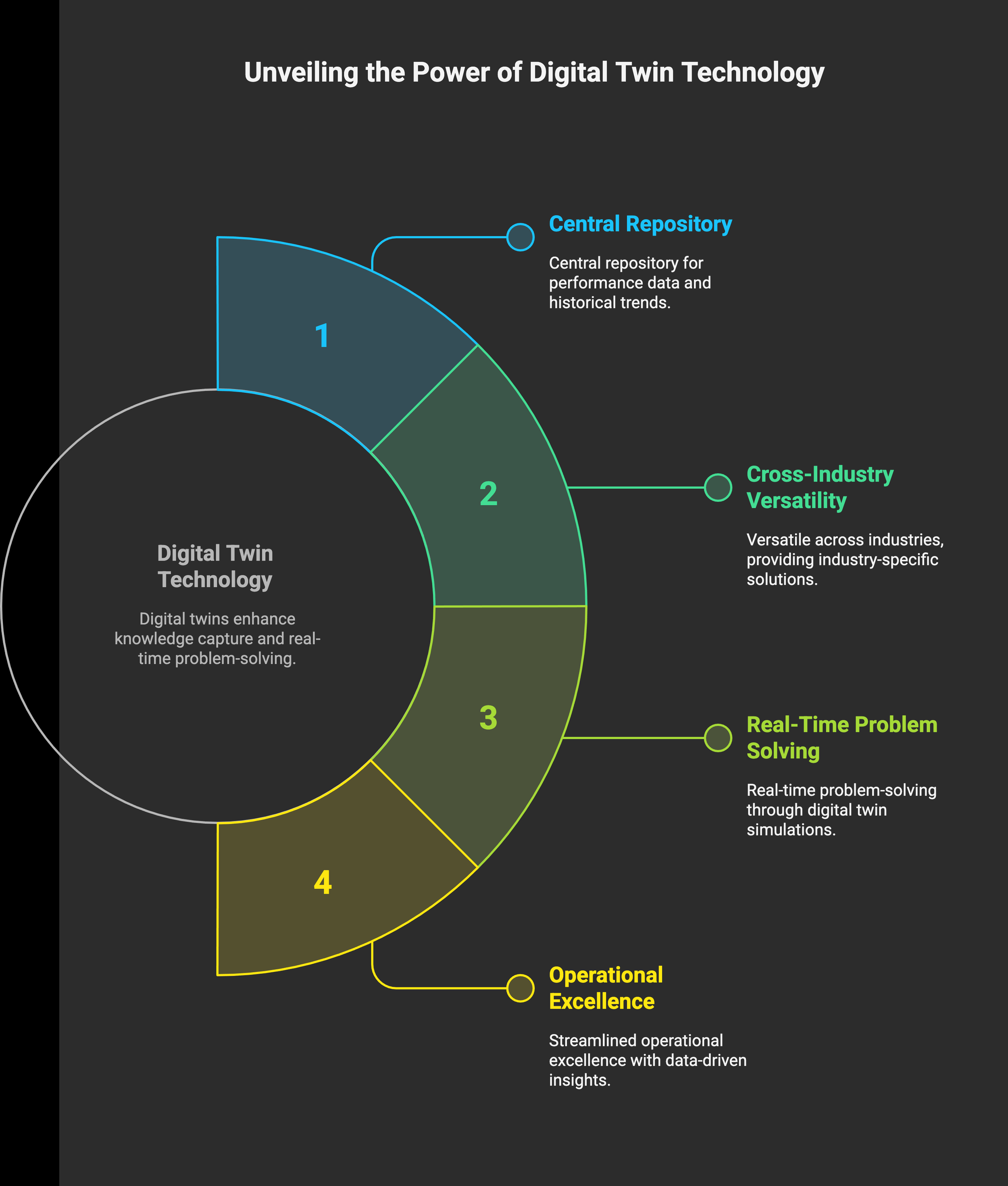

StriveGrid Engineering Guide Platform Digital Twin Technology

Real-Time Asset Monitoring

The platform incorporates data from IoT sensors, control systems, and field instruments to create and update digital twins of machines, pipelines, or other critical infrastructure. These twins mirror the real-time status of physical assets, allowing engineers and stakeholders to gain instant visibility into performance and health.AI-Powered Predictive Maintenance

The platform analyzes the data generated by the digital twins, applying AI algorithms and machine learning models to identify patterns and trends that signal impending equipment failures. This allows for proactive maintenance, preventing costly breakdowns and enhancing asset longevity.Optimizing Workflows and Processes

Simulation and Testing

The platform's digital twins can simulate various operational scenarios, allowing companies to test potential changes in workflows or equipment settings before implementing them in the physical world. This ensures that businesses can fine-tune their processes without disrupting production.Process Optimization

The platform also allows for process optimization based on the data from digital twins, which can identify bottlenecks or inefficiencies in real-time and suggest improvements. This helps companies reduce waste and lower operational costs.3D Printing Integration

The platform's integration with 3D printing technologies enables on-demand manufacturing and rapid prototyping, allowing for the immediate production of replacement parts and cost-efficient testing of new designs.Enhancing Safety with AI-Powered Risk Management

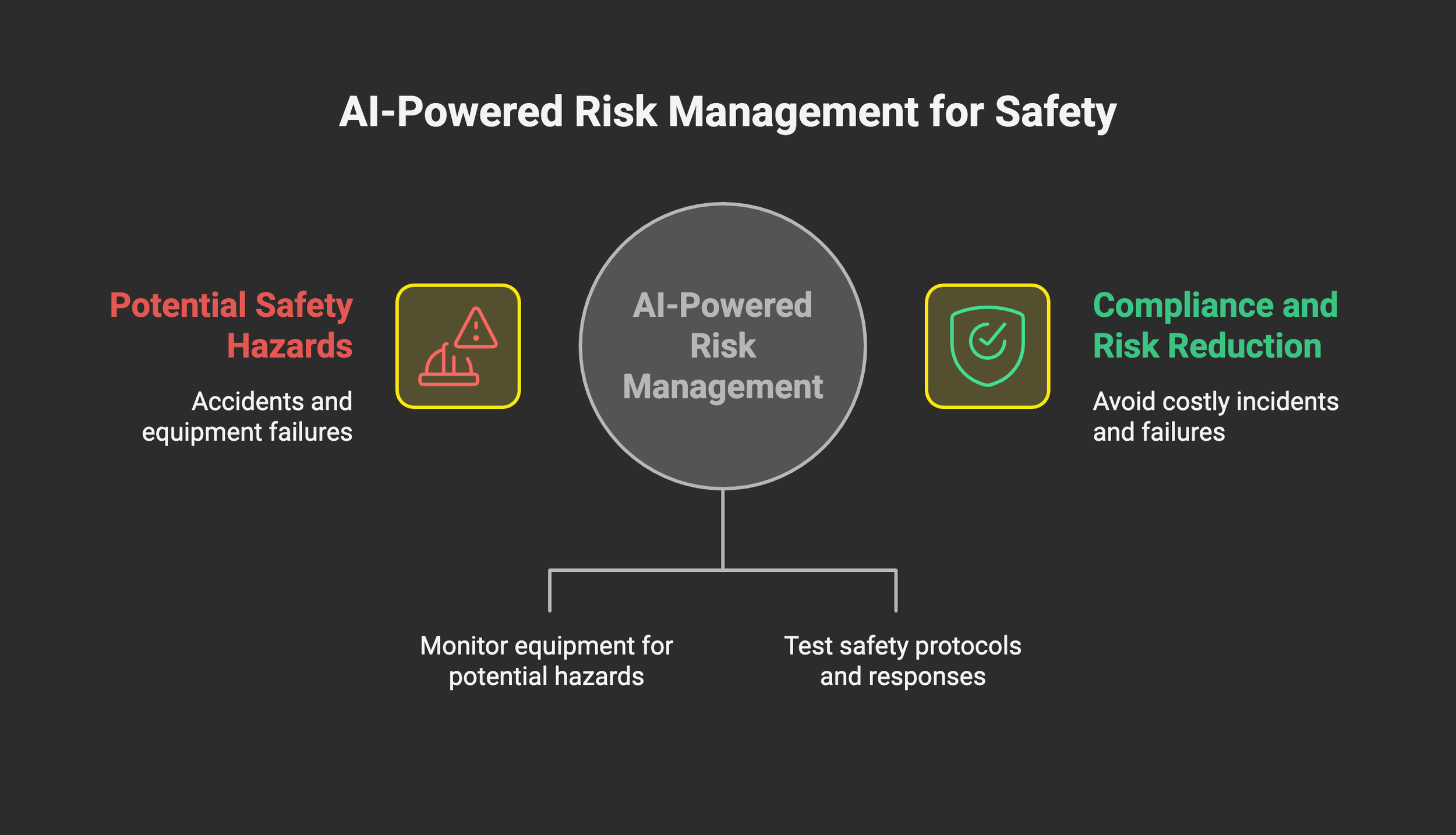

Predictive Analytics

The platform's digital twins continuously monitor equipment and operational conditions for potential safety hazards, such as pressure build-ups, extreme temperatures, or mechanical wear. AI algorithms analyze this data to predict high-risk scenarios before they occur, alerting engineers and operators to take preventive actions.

Scenario Simulation

The platform can also simulate emergency scenarios using the digital twins, helping companies test their safety protocols and response plans to ensure they are prepared for any eventuality.

Compliance and Risk Reduction

By predicting hazards before they escalate, the platform reduces the likelihood of accidents or equipment failures, helping companies comply with safety regulations and avoid costly incidents.

Supply Chain Optimization and Inventory Management

Supply Chain Visibility

The platform uses digital twins to monitor the availability and usage of raw materials, parts, and other inventory in real-time, allowing businesses to optimize their supply chain and avoid shortages.

Predictive Analytics

AI models can predict when critical inventory levels will be reached based on consumption trends, enabling just-in-time replenishment and cost savings through reduced excess stock and storage costs.

Risk Mitigation

The platform can also identify supply chain risks, such as transportation delays or supplier disruptions, and suggest alternative solutions to maintain production schedules and avoid costly disruptions.

Seamless Integration with AI and AR

AI-Powered Insights

Digital twins combined with AI can continuously analyze data from physical systems and predict equipment failures or performance issues. This aligns perfectly with the Hustler Joint System's emphasis on providing AI-powered visual inspections and real-time decision-making.

AR-Enhanced Workflows

Digital twins can feed real-time data into AR work instructions provided by the Hustler Joint platform. This means frontline workers will not only get visual guidance but also real-time updates on equipment conditions, enhancing troubleshooting and operational accuracy.

Remote Assistance

With the platform's remote expert assistance features, the digital twin can provide experts with a virtual model of the physical asset, allowing them to monitor the situation remotely, run simulations, and provide precise advice to workers on-site.

Knowledge Capture and Sharing

Central Repository

Digital twins can store and visualize performance data over time, capturing valuable insights and expert knowledge. This complements the Hustler Joint System's open-source platform by providing a central repository for performance data, historical trends, and best practices.

Cross-Industry Versatility

Digital Twin Technology is applicable across multiple industries (oil and gas, manufacturing, utilities, etc.), and the Hustler Joint System's platform is designed to serve a wide range of sectors. The integration provides industry-specific solutions, making the platform even more versatile and valuable.

Real-Time Problem Solving

The platform's core function of real-time problem-solving is amplified by digital twins. Engineers can simulate potential changes or repairs in the digital twin before applying them in the real world, reducing risks and optimizing solutions.

Operational Excellence

The combination of Digital Twin Technology with the Hustler Joint System Engineering Guide Platform creates a powerful, data-driven environment where operational excellence, predictive maintenance, and remote assistance are streamlined, elevating the platform's utility across various industries.

Revolutionizing Industrial Operations

•

Empowering Industries to Thrive

•

Revolutionizing Industrial Operations • Empowering Industries to Thrive •

-

The platform's AI-powered predictive maintenance capabilities allow for the early detection of equipment issues, preventing costly breakdowns and optimizing maintenance schedules.

-

The integration of 3D printing enables the immediate production of replacement parts, minimizing downtime and accelerating innovation cycles.

-

By simulating and testing potential changes, the platform helps companies fine-tune their processes, reduce waste, and improve overall operational efficiency.

-

Oil and Gas

In the oil and gas industry, the Hustler Joint System Engineering Guide Platform's integration with Digital Twin Technologies enhances asset monitoring, predictive maintenance, and supply chain optimization, driving operational excellence and safety.

-

Manufacturing

For manufacturing companies, the platform's capabilities in workflow optimization, 3D printing, and real-time problem-solving empower them to increase productivity, reduce costs, and stay ahead of the competition.

-

Utilities

In the utilities sector, the Hustler Joint System Engineering Guide Platform's integration with Digital Twin Technologies enables enhanced asset management, predictive maintenance, and risk mitigation, ensuring reliable and efficient service delivery.